MES

MES (Manufacturing Execution System)

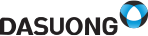

SMT Line

| Sortation | Computer Equipment | Role | Tracking Target | Note |

|---|---|---|---|---|

| SP | - PC (MES) - Barcode Reader |

- Started Production - Inter-Lock - Metal Mask, Squeegee - prevention of misapplication - Observe solder usage time |

- Production start history - Metal mask, Squeegee, Solder change history - Inter-Lock history |

- Calculate Metal mask, Squeegee Usage |

| SPI | - PC (MES) - SPI Vision Camera |

- Save the Test Result log | - PCB Panel S/N - Inspection result (OK/NG) |

- Save Detailed results |

| Mounter | - PC (MES) - PDA |

- Save the Mount History Log - Prevention of Misapplication - Calculate material requirements |

- History Prevention of Misapplication - Check Material Requirements (Mounted /loss amount) |

- Save Detailed results |

| W/T | - PC (MES) - Barcode Reader - Inter-Lock Device |

- PCB Mounting material matching - Collection SPI,AOI Log Data - Inter-Lock to SPI NG or untested PCB |

- PCB Board S/N - PCB Mounted Materials - History Inter-Lock |

|

| AOI | - PC (MES) - AOI Vision Camera |

- Save the Test Result log | - PCB Board S/N - Inspection Result (OK,NG DATA ,NG material Data) |

- Save Detailed results |

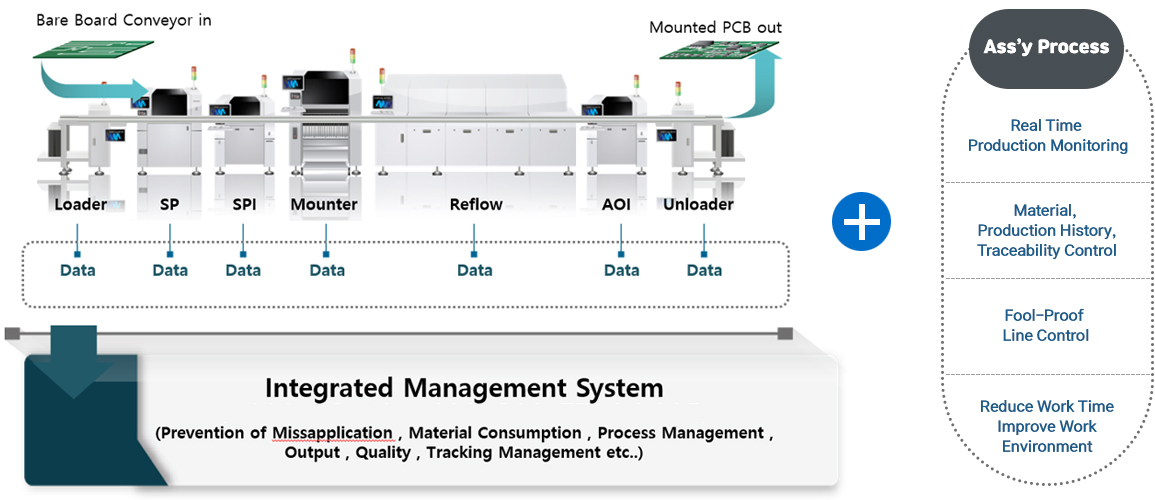

SET Line

| Sortation | Computer Equipment | Role | Tracking Target |

|---|---|---|---|

| Manual Ass’y & 1’st Function Test | - Notebook / Printer - Scanner |

- Started Production / Board Barcode Input - Board Barcode &Temporary Label Matching - Attach Temporary Label |

- Production start history - Defect in preceding process - Skip Process History |

| GPS | - Notebook - Scanner |

- Started Production - Input Temporary Label Barcode |

- Production start history - Defect in preceding process - Skip Process History |

| AGING | - Notebook - Wireless Scanner |

- Started Production - Input Temporary Label Barcode - Initialization |

- Production start history - Defect in preceding process - Skip Process History |

| Final Inspection | - Notebook - Scanner |

- Started Production - Input Temporary Label Barcode - Temporary / Real Label Matching - Attach Real Label |

- Production start history - Defect in preceding process - Skip Process History |

| OQC | - Notebook - Wireless Scanner |

- Make LOT - Sampling Inspection - SAMPLE |

- OQC Histoy |